Quality Assurance at Overseas Group Companies

Quality Assurance at Overseas Group Companies

Our goals and values are common to Japan, Europe, Asia, Oceania, the Americas, and Africa. We engage in quality assurance activities with both commonality in the rules and mechanisms that form the basis of our activities and uniqueness in accordance with regional characteristics.

We strive to meet the quality demands and expectations of not only consumers, but also stakeholders in various fields, through activities covering everything from water and raw ingredients to manufacturing processes and the products distributed in the market.

At our overseas group companies, we are also making efforts for mutual development by sharing various information quickly and effectively through cooperation and networks across areas. We are also increasing the sustainability of our activities by focusing on the development of human resources and further strengthening our foundation.

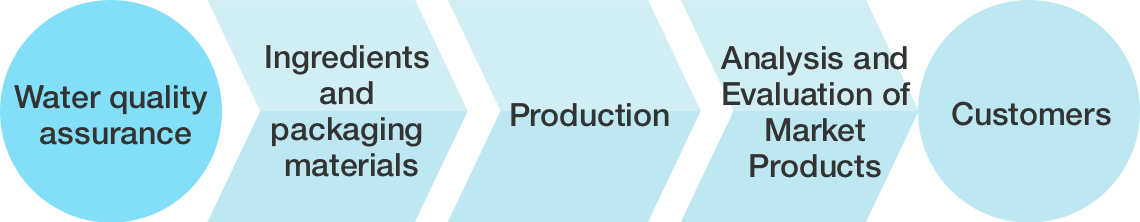

Quality assurance initiatives in each process

Water quality assurance

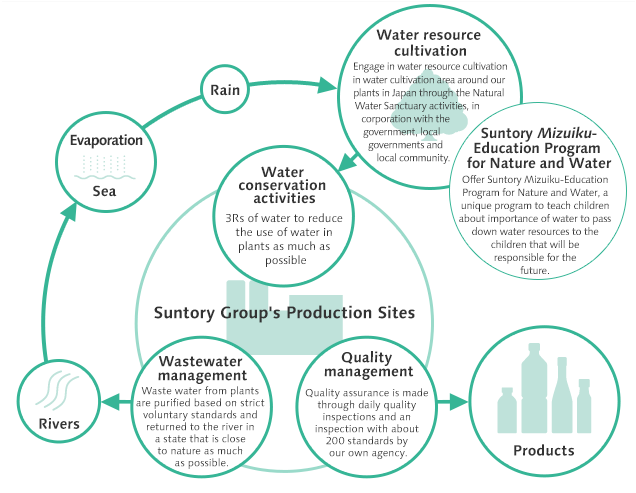

Our overseas group companies conduct the same annual analysis and evaluation of water used at plants as we do in Japan. We conduct risk assessments at 130 plants (including contractors and franchises) in 48 countries to control the quality of water used for manufacturing.

We make efforts in areas such as information systemization of risk management, upstream management of risk through water source assessments, response to new risks, and manage the results of the evaluation at headquarters.

Ingredients and packaging materials

A single product involves numerous suppliers who provide raw materials and packaging components. Within our overseas group companies, we operate under a unified supplier evaluation system. For raw materials and packaging deemed to pose potential risks, we conduct on-site quality audits by visiting the production facilities directly. These audits are carried out to assess the suppliers’ quality assurance systems.

Based on the audit results, we perform regular follow-up quality audits to ensure the consistent quality of raw materials and packaging used in our products.

Manufacturing

Our overseas group companies also promote quality assurance activities based on Suntory’s global quality policy, "All for the Quality." A robust framework has been established to ensure thorough implementation at manufacturing sites. Regarding product assurance levels, we apply a unified quality standard across the Suntory Group, enabling us to deliver safe, reliable, and delicious products to customers worldwide, regardless of where they are manufactured.

In addition, similar to our domestic factories, we actively pursue international certifications related to food safety and general hygiene. Beyond complying with the laws and regulations of the countries where our products are manufactured and sold, we are committed to sincere craftsmanship every day, striving to become the most beloved brand in each market.

Analysis and Evaluation of Market Products

In our overseas group companies, in addition to quality checks during manufacturing and shipping, a system is in place to regularly evaluate trade samples and provide feedback to product design and manufacturing processes. This initiative enables quality verification at the point when customers actually receive the product, contributing to ongoing quality improvement efforts.

-

*Trade Sample Evaluation:

Based on production volume, products distributed in the general market are assessed from various perspectives, including appearance and flavor analysis. This process ensures quality is maintained throughout manufacturing and distribution, and supports continuous improvement.

PQA* Initiative at CITRESA Carcagente plant in Spain

At our laboratory in Carcagente, Spain, daily evaluations are conducted on both final products shipped from manufacturing sites and products distributed in the general market, in order to maintain consistent quality across all items. The laboratory analyzes approximately 15,000 samples annually.

-

*PQA Product Quality Assurance