Environment

Packaging & Resource Efficiency

Policies and Our Approach

To build a recycling-oriented society, Suntory Beverage & Food (“the Company”) will promote problem-solving efforts together with various stakeholders. Each employee will work on taking responsible action to solve problems and take the initiative in bringing about a sustainable society.

Containers and packaging protect and preserve the quality of products until they reach customers. However, most end up becoming post-consumer waste. The Suntory Group, which includes Suntory Beverage & Food, recognizes the social and environmental impacts that containers and packaging cause and, in 1997, established Guidelines for the Environmental Design of Containers and Packaging. Designs are done in accordance with the Guidelines, for instance, by selecting material for labels and the color of glass bottles in consideration of recyclability. In addition, the Group engages in Life Cycle Assessment (LCA) efforts to reduce the environmental impact of containers and packaging.

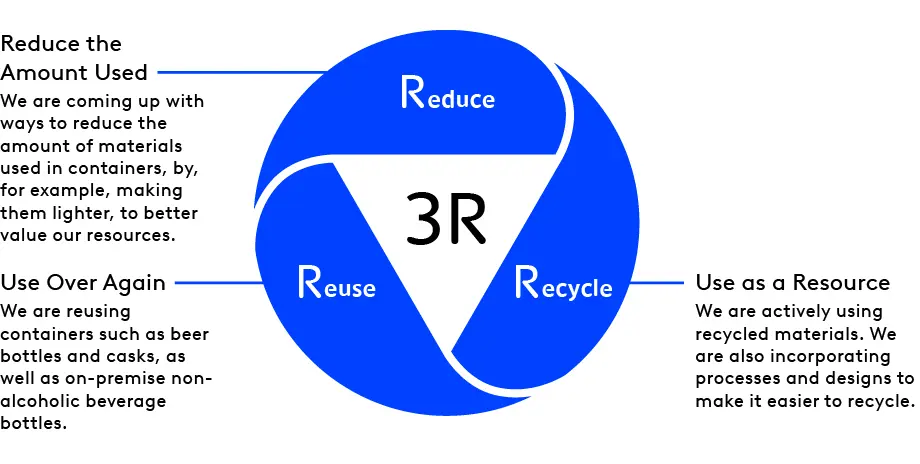

3Rs of Containers and Packaging

Under the 3R principles of Reduce, Reuse, and Recycle, Suntory Group develops containers and packaging with environmental considerations. We focus on user-friendly designs that consider actions from consumption to sorting of empty containers. Our efforts include reducing weight, adopting materials that lessen environmental impact, and designing for easier recycling.

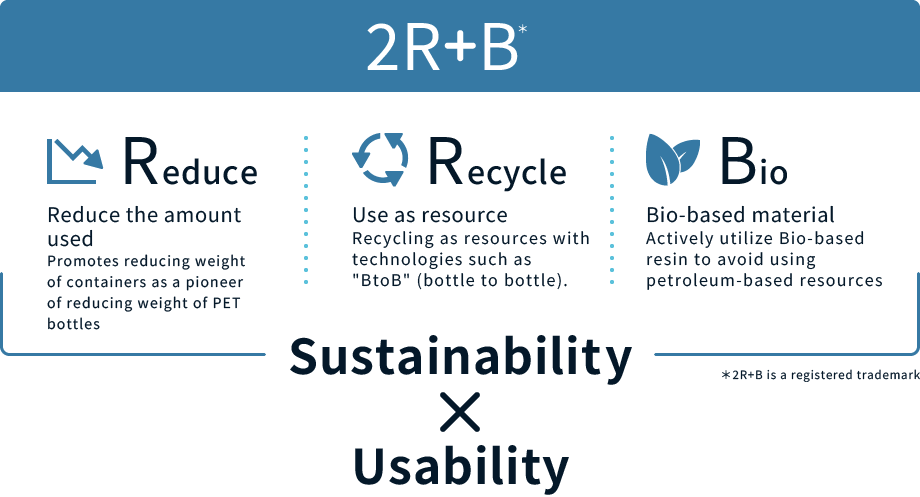

2R+B Strategy

For PET bottles, we are committed to maximizing resource efficiency by reducing resin usage and incorporating recycled materials. We aim to replace virgin petroleum-based materials with renewable alternatives to the extent possible. This approach is guided by Suntory Group's unique 2R+B (Reduce, Recycle + Bio) strategy.

Implementation Structure

Sustainability Committee

For more information on the Sustainability Committee, see Environmental Management

Targets and Progress

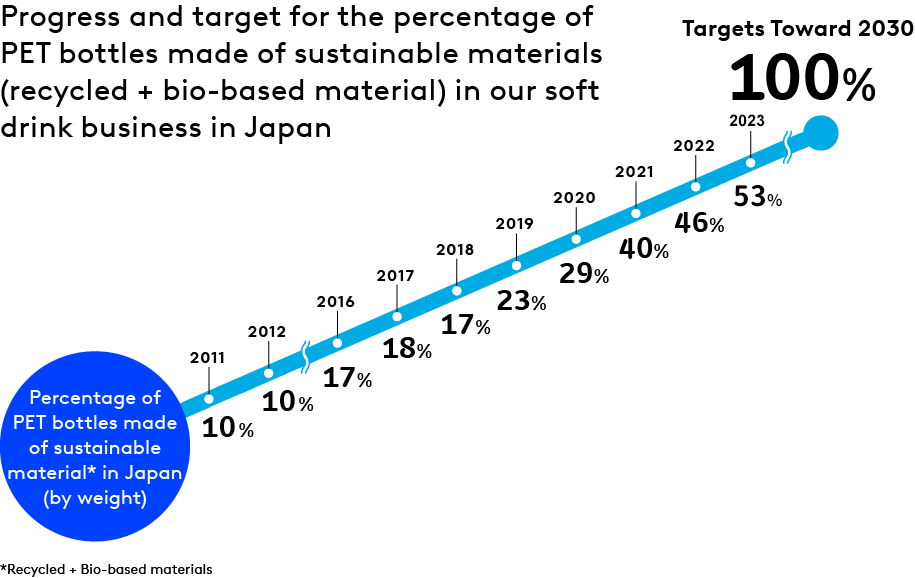

Percentage of Sustainable Materials Used in PET Bottles*

Targets

Toward

2030

- Switch all the PET bottles used globally to be made of recycled or plant-based material by 2030, achieving zero use of virgin petroleum-based materials.

2024

Progress

- Percentage of PET bottles made of recycled or plant-based material: 38%

- Japan

- 58%*

- Overseas

- 23%

-

*Ratio of the number of 100% sustainable bottle

Our Initiatives

Initiatives for Plastic

While plastic products have enriched our lives through their utility, improper handling after use has led to environmental impacts, becoming a significant social issue. In Japan, the Ministry of the Environment has formulated the “Plastic Resource Recycling Strategy” as a strategy to comprehensively promote resource recycling while recognizing the convenience of plastic products.

Suntory Group, including the Company, also established the Plastic Policy in 2019 to strongly lead the transformation toward a circular and net-zero society, focusing on PET bottle containers through the 2R+B (Reduce, Recycle + Bio) strategy. In line with this Policy, Suntory Group, including the Company, aims to make all PET bottles used globally 100% sustainable, using only recycled or bio-based materials by 2030, thereby eliminating the use of virgin petroleum-based materials.

Suntory Group Plastic Policy

Expressing gratitude toward the Blessings of Nature that are the source of Suntory’s products, the Suntory Group will provide strong leadership for transforming into a recycling-oriented and zero carbon society to bring about a world where diverse animal and plant life shines and resonates. With its diversity in usage and convenience, plastic has made our lives easier.

The plastic containers and packaging we use serve a useful function, but to prevent them from having a negative impact on the global environment, we will promote problem-solving efforts together with various stakeholders. Each employee of Suntory will work on taking responsible action to solve problems and take the initiative in bringing about a sustainable society.

- Recycle & Renewable:

- Aim to switch all the PET bottles used globally for Suntory products to be made of recycled or plant-based material by 2030, achieving zero use of virgin petroleum-based materials.

- Actively work and collaborate with government agencies, industry, environmental non-governmental and non-profit organizations for the measures necessary to develop an efficient recycling system based on the situation of each country where we do business.

- Reduce & Replacement:

Reduce the amount of plastic used by changing the design of containers and packaging and look for the introduction of alternative containers that do not negatively impact the environment in order to effectively utilize resources. - Innovation:

Actively invest in innovation for materials and processes that improve the recycling rate and minimize environmental impact. - New Behavior:

Promote activities that drive change in consumer behavior. Each Suntory employee will work to change their lifestyle, promote sorting and collection, and actively participate in social contribution activities such as cleaning up rivers and beaches.

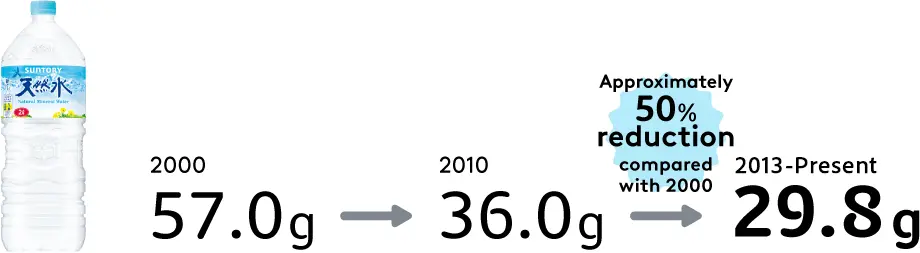

Reduce: Lightweighting

For approximately 20 years, Suntory Beverage & Food has been working to reduce the weight and thickness of PET bottles, caps, and labels. We strive to effectively use resources while maintaining and improving quality at the point of consumption (quality of contents and ease of bottle use).

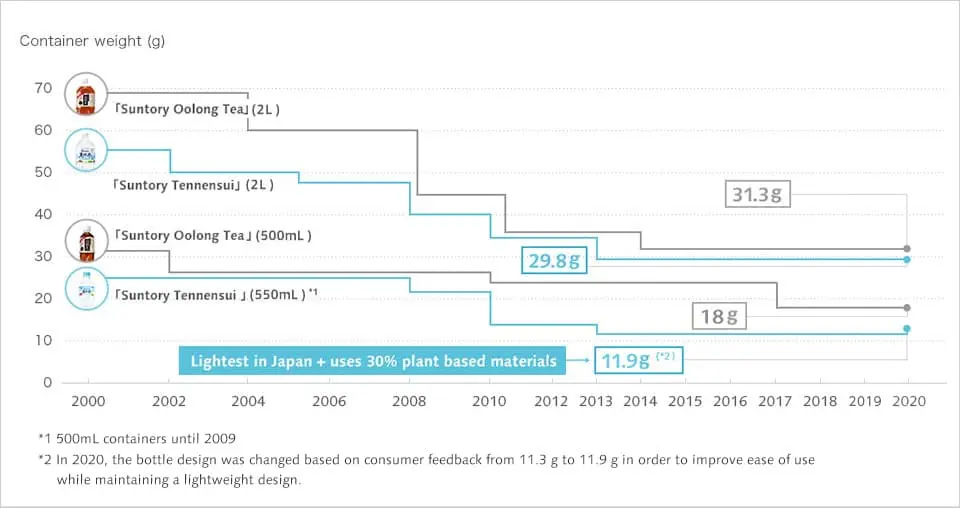

Change in Weight of 550-mL Suntory Tennensui PET Bottles*1

-

*1500-mL capacity through 2009

Change in Weight of 2-L Suntory Tennensui PET Bottles

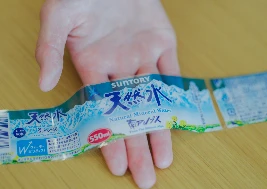

Introducing Record Breaking Thinnest Roll Label*1 for Plastic Bottle Beverages in Japan

We are reducing the weight of product labels on plastic bottles to reduce environmental impact. We commercialized the thinnest plastic bottle roll label in Japan at 16㎛ (micrometer*2) in 2012. In April 2014, we introduced an even thinner label for the 2L and 550mL PET bottles used for Suntory Tennensui mineral water which was only 12㎛ thick. Since then, we have been expanding its adoption to all of our products that use roll labels. This has allowed us to reduce CO2 emissions by 25%*3 compared to conventional labels (16㎛).

-

*1Labels that peel off from the glued area instead of peeling off at the perforations

-

*21/1,000mm

-

*3Reduction rate in the film (label) manufacturing process

12㎛ thick role label, thinnest in Japan

The Lightest Cap of Any PET Beverage Bottle in Japan

We are also reducing the environmental impact of the bottle caps on plastic bottles. Since September 2016, we have adopted 1.85g bottle caps, which are the lightest in Japan*1 that use 30% bio-based PET materials for Suntory Minami-Alps Tennensui mineral water. This innovation reduces the use of petroleum-derived raw materials by 35% and decreases CO2 emissions by 27% compared to conventional PET bottle caps.

In addition, we have further evolved our environmental efforts by using bio-based materials and in March 2019, we introduced polyethylene caps with 100% plant-derived ethylene*2 for 550ml Suntory Aso Tennensui mineral water, which is manufactured at our Kyushu Kumamoto Plant (Kamimashiki District, Kumamoto Prefecture). This innovation reduces the use of petroleum-derived raw materials by 90% and decreases CO2 emissions by 56%*3 compared to current PET bottle caps.

-

*1As of April 2023

-

*2Polyethylene caps with 100% plant-derived ethylene as the main raw material. Excluding trace amounts of petroleum-derived components and colorant components at the time of production line changeover.

-

*3One bottle of Suntory Tennensui Mineral Water (550mL)

Changes in Weight Reduction for Our Major PET Bottled Products in the Japanese Market

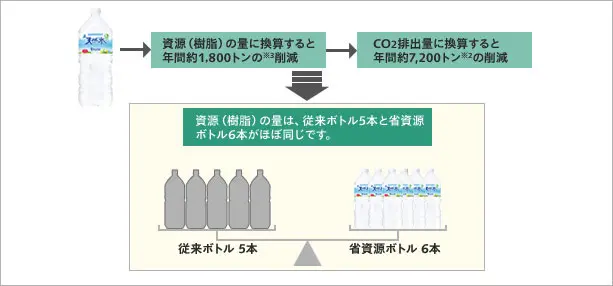

Example of CO2 Emissions Reduction for Signature Product (Suntory Tennensui mineral water 2L PET bottle)

-

*1As of April 2019

-

*2, 3Based on our calculations

Development of World’s Lightest* Heat-resistant PET Bottle in Southeast Asia Leveraging Japanese Technological Capabilities

The Japanese manufacturing technology and design capabilities for reducing weight of PET bottles have been used in Group companies in Europe and Asia. In 2020, we succeeded in developing the world’s lightest* PET bottle weighing 15 g in heat-resistant filled containers that also pursue functionality, versatility, and design. This heat-resistant PET bottle utilizes technology that prevents deformation of the bottle by dropping nitrogen to create positive pressure.

We have introduced this bottle to Suntory PepsiCo Beverage (Thailand) and Suntory PepsiCo Vietnam Beverage (Vietnam). We also have started using 100% recycled materials for these bottles from 2023.

-

*In the 450-mL class of heat-resistant PET bottles (as of April 2024, according to our own research)

Lightest Heat-Resistant Bottle with Liquid Nitrogen Injection in Southeast Asia

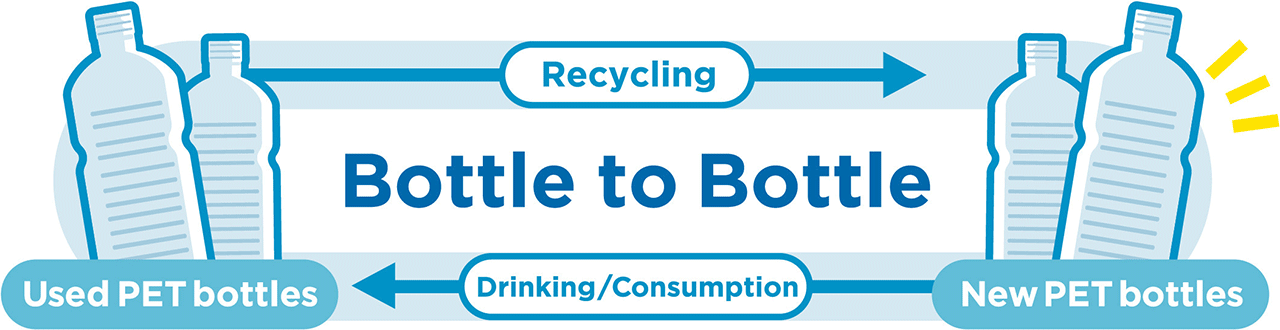

Recycle: “Bottle to Bottle” Horizontal Recycling

As the next step after lightweighting, and as a core activity toward achieving the 2030 goal of 100% sustainable PET bottles, is the “bottle-to-bottle” horizontal recycling process, where used PET bottles are transformed into new ones.

Starting with the introduction of 100% recycled PET bottle*1 in 2012—the first in Japan's soft drink industry—we have been advancing “bottle-to-bottle” horizontal recycling. We also developed the world’s first “FtoP direct recycling technology,”*2 which reduces CO2 emissions compared to conventional methods.

-

*1Mechanical recycling

-

*2Joint development among 4 companies including Kyoei Sangyo Co., Ltd

Initiatives in Japan

“Bottle to Bottle” Horizontal Recycling

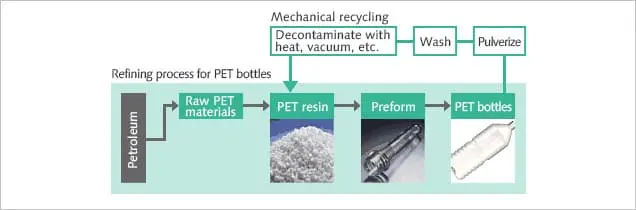

“Bottle to bottle” horizontal recycling refers to recycling used PET bottles into new ones. PET bottles are resources that can be recycled many times, which can help reduce the use of virgin petroleum-based materials and CO2 emissions. “Bottle to bottle” horizontal recycling through mechanical recycling* is a recycling method with low environmental impact (in terms of CO2 emissions during processes from raw material procurement to preform production).).

-

*Mechanical recycling: A method in which recycled resin—obtained by crushing, washing, and otherwise processing used PET bottles into a raw material to be used for new PET bottles—is further processed under high temperature and reduced pressure for a certain period of time to remove impurities in the recycled material and make PET resin of suitable quality for beverage containers.

Changes in Initiative to Use 100% Sustainable PET Bottles

For over a decade, Suntory Beverage & Food has been pioneering efforts toward a sustainable society by collaborating with partner companies on horizontal recycling, transforming used PET bottles into new beverage bottles. In 2011, In collaboration with Kyoei Sangyo Co., Ltd., we established the Japanese soft drink industry’s first “bottle to bottle” mechanical recycling system. The following year, in 2012, we launched the industry’s first 100% recycled PET bottle*1. This marked the beginning of a series of technological innovations, including the development of the world’s first F-to-P direct recycling technology,*2 which reduces CO2 emissions compared to conventional alternatives. With these and other initiatives, we have been furthering technological innovation and proactively commercializing and promoting “bottle to bottle” horizontal recycling over many years.

In 2019, we also established the Suntory Group Plastic Policy. In it, we set a target of achieving 100% sustainable PET bottles, switching all PET bottles used globally to 100% recycled or bio-based materials, eliminating the use of virgin petroleum-based materials by 2030. We are engaged in various initiatives to achieve this. By 2024, we expanded our use of sustainable materials (recycled or bio-based materials) to account, by weight, for 58% of all PET bottles for our soft drink business in Japan.

-

*1Through mechanical recycling

-

*2Abbreviation of “Flake to Preform.” Developed in collaboration with Kyoei Sangyo Co., Ltd. and other three companies

Proactive Introduction of Recycled PET Bottles

The Suntory Group is promoting the adoption of recycled materials as part of its efforts to meet its goal of making its PET bottle use 100% sustainable by 2030. The Group adopted PET bottles made from 100% recycled materials for all bottles of GREEN DAKARA Yasashii Mugicha (680mL, 600mL) sold in Japan, as well as many products, including Craft Boss and Iyemon. It also adopted a new logo mark to convey that PET bottles can be recycled numerous times: “Bottles are Resources! Towards a Sustainable Bottle.” The Group has rolled out this mark to all PET bottles to expand communication with consumers. It is also moving to use of PET bottles made from 100% recycled materials for products other than soft drinks sold in Japan, such as 720mL PET bottles used in its domestic wine business. Going forward, we will accelerate these efforts across all of its operations.

-

*New logo, “Bottles are resources! Towards a Sustainable Bottle”

-

Yasashii Mugicha 680mL

-

New logo, “Bottles are resources! Towards a Sustainable Bottle”

Promote horizontal recycling in collaboration with businesses and local governments

As we strive to bring about a recycling-oriented society, we are working in collaboration with businesses and local governments to recycle used PET bottles into new PET bottles through bottle-to-bottle horizontal recycling.

We have made agreements concerning horizontal recycling with retailers, commercial facilities, and the like. We recycle used PET bottles collected in places like store fronts into PET bottles for our company's beverages using bottle-to-bottle horizontal recycling. At the same time, we hold events aimed at educating consumers.

By making similar agreements with local governments, we now are recycling PET bottles, previously being discarded by residents, as resources for PET bottles for Suntory beverages. We also conduct educational classes about PET bottle recycling at elementary and junior high schools in the municipalities with which we have agreements.

Developing Bottle-to-Bottle Horizontal Recycling

In 2011, in collaboration with Kyoei Sangyo Co., Ltd., Suntory Group established the Japanese soft drink industry’s first “bottle to bottle” mechanical recycling system*1 and, in 2012, published a joint research paper*2 on the safety evaluation of recycled PET bottles. Since its introduction in 2011, this system has received several environmental awards and has been recognized as a pioneering example of sustainable resource circulation.

“Bottle to bottle” horizontal recycling using mechanical recycling method makes it possible to recycle PET bottles as a resource over and over again, without using virgin petroleum-based materials. In addition, it reduces CO2 emissions by approximately 60%*3relative to manufacturing PET bottles from virgin petroleum-based materials.

Of the PET bottle recycling systems that have been adopted in Japan, mechanical recycling is the most efficient method in terms of costs and has the lowest environmental impact (CO2 emissions).*4While the recycling process may add some color to the bottles, it does not affect the quality or safety of the containers in any way.

-

*1Mechanical recycling system: A method in which recycled resin—obtained by crushing, washing, and otherwise processing used PET bottles into a raw material to be used for new PET bottles—is further processed under high temperature and reduced pressure for a certain period of time to remove impurities in the recycled material and make PET resin of suitable quality for beverage containers.

-

*2Japanese Journal of Food Chemistry and Safety, Vol. 19 (1), 2012, pp. 7–13

-

*3Processes from used PET bottles to the preform production

-

*4Based on our research

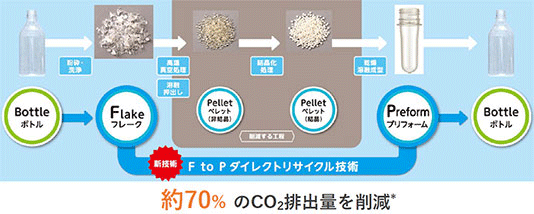

Adoption of F-to-P direct recycling technology

In 2017, we collaborated with Kyoei Sangyo Co., Ltd. and overseas machinery manufacturers (EREMA in Austria and SIPA in Italy) to develop F-to-P direct recycling technology, which promises to further reduce our environmental impact. We began production in the fall of 2018. F-to-P direct recycling technology is a technology that can directly manufacture preforms after melting and filtering flakes made from collected PET bottles that have been crushed and washed at high temperatures. The F-to-P direct recycling technology can reduce CO2 emissions by 70%* compared with PET bottles made of virgin petroleum-based materials.

Products that use F-to-P direct recycling technology

F-to-P direct recycling technology process

-

*Compared to use of virgin petroleum-based materials

Promoting Bottle-to-Bottle Horizontal Recycling by Improving Containers and Packaging

In order to further promote “bottle to bottle” horizontal recycling, we believe that making it easy for consumers to sort their PET bottles from other waste is an important factor.

Suntory Group therefore introduced label-free bottles in 2020 and have adopted them for flagship products including the Suntory Tennensui (Mineral Water), Craft Boss, and Iyemon brands. This move eliminates the task of removing bottle labels, making it easier to prepare them for recycling. We hope this will contribute to further encouraging “bottle to bottle” horizontal recycling.

In addition, we developed and launched in April 2023 a new 2L PET bottles for Suntory Tennensui that is easy to crush down to approximately one-sixth of its original size when empty. This new bottle resolves frustrations related to storing empty PET bottles in the home until recycling collection day, such as bottles taking up space or popping back to their original size even after crushing. By making it a more satisfying process to engage with, we also hope to encourage customers to remove caps and labels when they sort their bottles for recycling, leading to higher-quality PET bottle recycling.

Expanding Horizontal Recycling Awareness-raising Activities

To realize a sustainable society, Suntory Group has been working to promote understanding of horizontal recycling initiatives and encourage proper sorting of used PET bottles by engaging in events such as seminars for external audiences. In 2021, we signed an agreement with Waseda University on the realization of a resource-circulating society, and we are also making efforts for the next generation. At elementary and junior high schools in municipalities with which we have concluded “bottle to bottle” horizontal recycling agreements, we offer educational programs on the importance of promoting “bottle to bottle” horizontal recycling and how to properly sort PET bottles, providing an opportunity for students to think about recycling and resource circulation. At companies with which we have concluded these agreements, we also hold educational seminars for employees and events for their families.

Communication with Consumers

Since 2022, driven by the desire for people to view PET bottles not as garbage but as a resource, and of recycling bins not as garbage bins but as something more like postal boxes that “deliver” the resource to the next person, we have been holding “PET bottle post” events and proactively communicating with consumers and engaging in awareness-raising activities on the theme of proper sorting not only at home but also when out and about.

Plastic bottle post

Promoting Horizontal Recycling Through Industry Cooperation

Starting in the fall of 2022, we have begun gradually rolling out recycling bins with industry-standard specifications in outdoor areas where there is a lot of contamination. New recycling boxes with innovations such as a downward-facing insertion slot have been shown to reduce the amount of foreign matter put into them. This brings improvement of the quality of recycling and contributes to “bottle to bottle” horizontal recycling. Using recycling boxes with industry-standard specifications will improve efficiency for vending machine operators and recycling processes and promote PET bottle resource circularity.

For more details, please see Japan Soft Drink Association website

Initiatives outside Japan

Introduction of Recycled PET Bottles at Overseas Locations

To achieve the 2030 fully sustainable PET bottle goal, Suntory Beverage & Food Europe aims to achieve 50% recycled contents in its PET bottles by 2025 or sooner.

Suntory Beverage & Food Europe brand Ribena was the first soft drinks brand in the UK to use a 100% PET bottle made from recycled plastic in 2007.The company has been increasing its use of recycled plastic - in 2021 this included the introduction of 100% recycled PET in May Tea and Pulco in France. In 2022, Suntory Beverage & Food Europe has started 100% recycled PET bottles in its Lucozade Sport brand in the UK and Ireland.

Suntory Beverage & Food Asia Pacific, with its main operations in Vietnam and Thailand, is also strengthening its efforts on recycling and has introduced the company's first 100% recycled PET bottles in Vietnam in 2022.

Ribena with 100% sustainable PET bottle

Developing New Technology to Drive Horizontal Recycling

Suntory Beverage & Food Europe is investing in a French green biotech company Carbios' enzymatic PET recycling technology through a consortium with L'Oréal, Nestlé Waters and PepsiCo. Carbios' optimized enzyme breaks down any kind of PET plastic (regardless of color or complexity) into its building blocks, which can then be turned back into like-new, virgin-quality plastic. In June 2021, Carbios produced the world's first food-grade PET plastic bottle prototypes made entirely from enzymatically recycled plastic which was showcased in the company's Orangina brand. In September 2021, Carbios successfully launched a demonstration plant and aims to build an industrial facility by 2027.

This technology is expected to enable an end recycled product on par with virgin PET, even when using source PET bottles not optimally separated from other waste or including a high proportion of colored PET bottles (common in Europe).

* Based on our research

Bio: PET Bottles Using Plant-Based Materials

To achieve 100% sustainable PET bottles, Suntory Group, including the Company, prioritizes “bottle-to-bottle” horizontal recycling for its low environmental impact, aiming to repeatedly circulate PET bottles as resources in a sustainable society. However, in the broader beverage market, new resources are needed for recycling into products other than PET bottles and to accommodate market growth. Consequently, alongside promoting “bottle-to-bottle” recycling, we are developing bio-based PET bottles to supplement the shortage of recycled materials.

In 2013, we introduced PET bottles with 30% plant-based materials for “Suntory Natural Water” in the 550ml size, and since 2023, this has been expanded to all 2L bottles as well. In 2013, we introduced PET bottles with 30% plant-based materials for Suntory Tennensui (mineral water)550-mL PET bottles, and since 2023, this has been expanded to all 2L bottles as well.

Suntory Group and the U.S. biotech venture Anellotech are collaborating on the development of 100% plant-based PET bottles. In 2019, the team succeeded in producing “paraxylene,” a precursor that constitutes 70% of PET bottle material, from non-food plant-based sources (wood chips) that do not impact the food supply chain. By 2021, the team successfully developed prototypes of 100% plant-based PET bottles using this technology, marking a significant step toward commercializing PET bottles made entirely from plant-based materials without affecting the food supply chain.

-

*Excluding some products for vending machines

PET bottle using 100% plant-based material (right)

Current PET bottle (using 30% plant-based material) (left)

Adoption of bottle cap that uses 100% bio-based PET materials*1

We are also reducing the environmental impact of the bottle caps on plastic bottles. Since September 2016, we have adopted 1.85g bottle caps, which are the lightest in Japan*2 that use 30% bio-based PET materials for Suntory Minami-Alps Tennensui mineral water. This innovation reduces the use of petroleum-derived raw materials by 35%*3 and decreases CO2 emissions by 27% compared to conventional PET bottle caps.

In addition, we have further evolved our environmental efforts by using bio-based materials and in March 2019, we introduced polyethylene caps with 100% plant-derived ethylene*2 for 550ml Suntory Aso Tennensui mineral water, which is manufactured at our Kyushu Kumamoto Plant (Kamimashiki District, Kumamoto Prefecture). This innovation reduces the use of petroleum-derived raw materials by 90% and decreases CO2 emissions by 56% compared to current PET bottle caps.

-

*1Polyethylene caps with 100% plant-derived ethylene as the main raw material. Excluding trace amounts of petroleum-derived components and colorant components at the time of production line changeover.

-

*2As of April 2023

-

*3One bottle of Suntory Tennensui Mineral Water (550mL)

Cooperation with Stakeholders

Initiatives for Recycling Used Plastic

R Plus Japan Ltd. was established as a joint venture by 12 companies (including Suntory Group and the Company) across the value chain for the purpose of contributing to resolving plastic-related challenges and achieving a sustainable society. Operations began in June 2020, and as of March 2025, the initiative has expanded to include 48 companies and is working with Anellotech to develop technologies to recycle used plastics to be recycled efficiently.

Currently in Japan, it is said that many plastics other than PET bottles are incinerated*. This new technology involves chemical recycling that directly converts general plastics, including PET bottles, back into basic chemicals (such as benzene, toluene, xylene, ethylene, and propylene) that serve as raw materials for plastics. This process requires fewer steps than traditional chemical recycling methods that go through an oilification process, helping to reduce CO2 emissions and energy consumption. We expect that once established, this technology will allow for more efficient recycling of a larger amount of used plastics.

R Plus Japan aims to address global plastic issues by developing technology and implementing it socially through cross-industry collaboration.

-

*Includes thermal recovery (heat utilization), in which heat generated during incineration is recovered and utilized for power generation and heat supply

Social Activities

Suntory Beverage & Food employees strive to change their lifestyles, practice sorting and collection, and actively participate in social contribution activities such as cleaning up rivers and beaches. In September 2022, Suntory PepsiCo Vietnam Beverages conducted a beach cleanup near Hanoi, Vietnam in cooperation with Ocean Conservancy, a global marine nature conservation organization, with participants, including employees and their families.

Alliance Membership

Joined the Clean Ocean Materials Alliance (CLOMA)

Suntory Group, including the Company, has been a member of the Japan Clean Ocean Material Alliance (CLOMA) since its inception in 2019. CLOMA is a public-private alliance established at the call of the Ministry of Economy, Trade and Industry. Through this alliance, we aim to collaborate closely with government agencies and industries to develop and promote the use of alternative materials for plastics, and aim to build an efficient recycling system that meets the needs of each country through information dissemination and technical consulting services to overseas countries.

Joined the Global Plastic Action Partnership (GPAP)

In 2019, the Suntory Group, which includes Suntory Beverage & Food, joined the Global Plastic Action Partnership (GPAP), a global alliance dedicated to solving environmental challenges caused by plastics.

-

*The GPAP is a global alliance for a circular economy of plastics, created by a public-private partnership based on the World Economic Forum with the aim of solving environmental challenges caused by plastics. Its members include the governments of the United Kingdom and Canada, as well as a wide range of businesses, investors, experts, NGOs, and other citizen organizations. In addition to exchanging information and sharing best practices at the global level and is engaged in community-based project activities at the local level.

WWF Japan’s Plastic Circular Challenge 2025*

In 2022, the Suntory Group, which includes Suntory Beverage & Food, joined the Plastic Circular Challenge 2025 organized by WWF Japan (World Wide Fund for Nature Japan) with the aim of realizing a sustainable society.

-

*The Plastic Circular Challenge 2025 is a framework for companies to respond to WWF Japan’s call for action to solve the problems of plastics. Participating companies have set a milestone year of 2025 as their commitment to containers and packaging and single-use plastics, and will promote activities based on a “Sustainable Circular Economy” approach.

Cans/Cardboard

Reduce: Lightweighting

Lightweighting in Cans

Suntory Beverage & Food is furthering the lightweighting in cans such as those used for coffee by aiming to dramatically reduce the amount of resources that are used while maintaining usability for customers. Steady promotion of even more lightweighting is underway with the introduction of thinner bodies even in steel cans for coffee.

Boss Rainbow Mountain Blend

Reducing the Weight of Cardboard

To reduce environmental impact, we are using short-flap cardboard cartons in cooperation with the industry, beginning with their use for beverages in small PET bottles since the spring of 2012. Through this, we have reduced the use of paper by about 20% compared to conventional cardboard cartons.

Short-flap cardboard carton with less cardboard used on its sides

Recycle: Promoting Recycling

Achieved 100% Use of FSC®-certified Cardboard

The Suntory Group is gradually adopting paper packaging materials that have acquired the FSC certification*1 that ensures proper management of international forests for products made in Japan. Suntory Beverage & Food introduced FSC-certified cardboard packaging to Suntory Tennensui mineral water for products manufactured from August 2017. Since the end of February 2018, we have achieved 100% use of FSC-certified cardboard used for packaging all our Suntory Tennensui brand products. We are promoting the use of FSC-certified paper packaging materials throughout the Group with the sequential adoption of these materials for Suntory Beverage & Food products and as packaging for six packs.

-

*Forest Stewardship Council (FSC) is an international organization that certifies timber produced from forests globally as well as the distribution and manufacturing processes of the cut timber. This certification considers the environmental conservation of these forests and recognizes timber produced in an economical and sustainable manner which generates revenue for the local community. This certification considers the environmental conservation of these forests and recognizes timber produced in an economical and sustainable manner which generates revenue for the local community.

Overview of Waste Management

Promoting Waste Reduction and Recycling

As part of Suntory Beverage & Food's efforts to establish a recycling-oriented society, the Company is working to reduce emissions of by-products and waste and to achieve 100% recycling.

Suntory Beverage & Food Europe has set a goal of zero waste from its factories and is engaging in waste-reduction and recycling activities. Moreover, it has set a target of reducing food waste from products by 50%, and is donating surplus products to charitable organizations to support people struggling with poverty as part of its efforts to achieve this target.

For By-products and Waste Generation Performance, see “Performance Data”

Initiatives for Collecting Containers and Packaging

Efforts to Prevent Scattering of Empty Containers

To beautify the environment and promote effective use of resources, we are engaged in activities to prevent the scattering of empty containers. We place one empty container collection box at every vending machine. We are also making efforts to raise awareness about recycling by affixing a Beautification Mark on vending machines as a way to prevent littering.

Placing Industry-Standard Recycling Bins with New Functions Next to Vending Machines

Starting in the fall of 2022, the Suntory Group has begun gradually rolling out recycling bins with industry-standard specifications in outdoor areas where there is a lot of discarded waste. New recycling bins with innovations such as a downward-facing insertion slot have been shown to reduce the amount of non-recyclable trash put into them. The Group is focusing on collecting used PET bottles from vending machines to promote horizontal recycling. In addition, improving the quality of the empty soft drink containers collected will improve efficiency for vending machine operators and recycling processes and promote PET bottle resource circularity. The Suntory Group will continue to utilize the recycling bins next to vending machines as a gateway to resource recycling, and raise awareness that these bins are not waste bins but recycling bins.