Social

Quality Management

Policies and Our Approach

Suntory Beverage & Food (“the Company”) aims to be the most trusted and beloved beverage company and is committed to improving the quality of its products and services.

Suntory Group's “All for the Quality” policy puts quality first and is based on our founder’s philosophy of crafting excellent products for consumers.

Under this quality policy, Suntory Group has established the Suntory Quality Management Regulations and the Rules for Suntory Quality, with which each Group company must comply. We strive to improve quality in all processes throughout the value chain, from R&D, product planning and design, to raw material procurement, manufacturing, logistics, and sales. We also believe it important that each and every Suntory Group employee is always aware of the importance of quality in carrying out activities, so we regularly hold quality education and awareness programs through in-house training and other programs.

All Suntory Group employees, including those outside Japan, constantly work to maintain and improve quality in order to earn even greater trust from consumers.

Implementation Structure

Suntory Beverage & Food is committed to maintaining and improving the quality of the products and services we provide. In order to provide the best quality of our products and services, meet the expectations of our customers, and continue to fulfill our social responsibility, we are promoting quality management throughout the company.

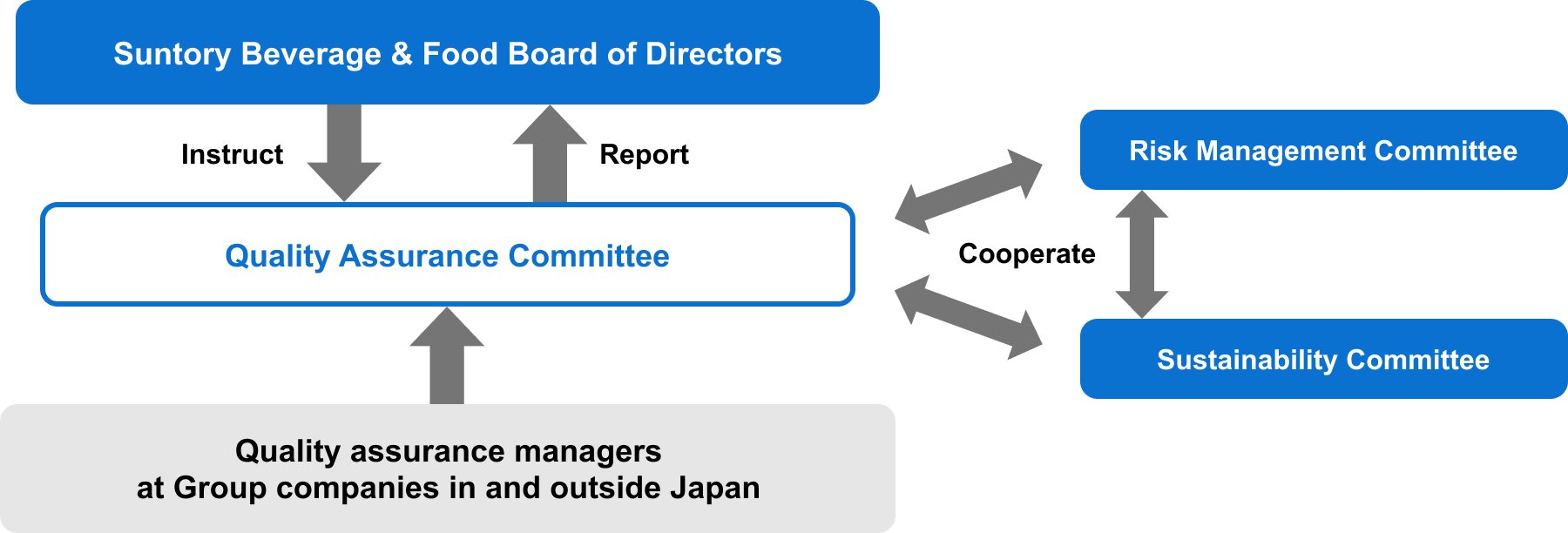

We have established a Quality Assurance Committee to address key challenges on a cross-sectional basis in line with the Group's common quality strategy.

Suntory Beverage & Food shares and deploys the Suntory MONOZUKURI Values with group companies outside Japan. These shared values represent the philosophy and action guidelines for craftsmanship that the Suntory Group has cherished since its founding.

Quality Assurance Implementation Structure at Suntory Beverage & Food

Quality Management System

All of Suntory Beverage & Food’s 10 plants in Japan have acquired certification in the international standards ISO 9001 (quality) and FSSC 22000 (food safety). In operations outside Japan, group companies have acquired certifications including ISO 9001 and FSSC 22000 as well as other certifications such as in halal food and beverage production, according to local business characteristics.

Our Initiatives

Quality Assurance across the Value Chain

Based on the Suntory Quality Policy “All for the Quality,” we continually work to maintain and improve quality in all our processes across the value chain, from R&D, product planning and development and the procurement of raw materials to manufacturing, distribution, and sales.

The main quality assurance activities for each process are as follows.

Water, Agricultural crops, and Natural resource

Safety Management for Ingredients and Water

The water, crops, and natural resources used in our products are carefully managed, and we ensure safety by assessing potential risks from various perspectives. We maintain strict management of raw ingredients suppliers and conduct thorough quality inspections. We also work to preserve the environment around water resources to ensure a stable supply of quality water.

-

●Regular analysis and inspection

-

●Development of new water resources

-

●Research into water quality in Japan and overseas

-

●Evaluation and selection of suppliers

-

●Quality auditing of suppliers

-

●Developing new ingredients and sustainable procurement

Regular inspection of water at the Safety Science Institute

Production site visits

(Florida, U.S.A.)

Research and technology development, Product planning and design

R&D and Technological Innovation

We passionately engage in research and technological development to create attractive products that exceed consumer expectations. We use evidence-based evaluation methods to verify new materials and technologies, contributing to the improvement of product performance and taste.

Product Planning and Design

We are committed to designing and delivering to consumers products that maximize the original flavor of ingredients. We clarify quality requirements from the product concept stage, and ensure that everything from package design to labeling is both easy to understand and compliant with legal requirements.

-

●Designs that pursue good taste and functionality

-

●Risk assessment, from an analytical chemistry perspective, microbiological perspective, and biological perspective, of the products to be manufactured and sold, and safety analysis and inspections

-

●Evaluation of regulatory conformity for constituent materials

-

●Developing new containers and sustainable procurement

-

●Performance and safety evaluation

Accurate labeling using easy-to-understand language

-

●Compliance of food labeling regulations and standards for all products

Manufacturing

Quality Management at the Manufacturing Stage

To provide high-quality, safe and reassuring products, each of our manufacturing plants implement thorough quality control. Our manufacturing lines use a combination of automated inspection equipment and human eye checks to prevent contamination with foreign substances and maintain hygiene, preventing the outflow of defective product.

-

●Acquisition of ISO9001 certification, HACCP (Hazard Analysis Critial Control Point)recognition, and FSSC22000 recognition

-

●Adoption of TPM(Total Production by foreign objects

-

●Preventing and checking damage to containers, spillage of contents, and contamination of contents by foreign objects

-

●Strengthening of food defense, including room exit/entrance management and installation of cameras

-

●Safety, function, and other inspections by expert teams of premium gifts

Delivering

Quality Assurance at the Logistics Stage

In order to maintain product quality, we take the utmost care for logistics. For example, we control temperature and humidity in our warehouses and take measures to reduce vibrations and shocks during transportation to help ensure that product quality remains intact throughout distribution. Additionally, we ensure traceability, enabling us to quickly identify and address any potential issues with raw materials, containers, or labeling after shipping.

Sales

We also carefully manage store and vending machine stocks, striving to maintain quality until our products reach our customers. We also utilize customer feedback to improve our products and services so that we can provide products and services that resonate with our customers.

-

●Sharing quality assurance knowledge with logistics companies

-

●Checking facilities, temperature, safety and hygiene in warehouses for product storage

-

●Vending Machine Maintenance and Product Management

Customers

Customer Response System

The Customer Center provides post-sale information to help ensure correct understanding of Suntory products and to build trust.

Suntory Group's Quality Initiatives Website

-

*Traceability

Ingredient traceability system such as using two-dimensional codes and social quality assurance activities related to sustainable procurement to realize a sustainable society

Accurate and Easy to Understand Labeling

In terms of product labeling, the Group Quality Assurance Division has established a system to check legal compliance and appropriateness, and promotes accurate labeling and easy-to-understand expressions in collaboration with the relevant teams including development and production of each Group company.

Examples of Labeling on Products

Allergen labeling

Suntory Group assesses raw materials determine the necessity to be indicated on products as allergenic. For our soft drinks, we not only comply 8 mandatory items required to put on the label by the Food Labeling Standards set by the Consumer Affairs Agency, but also include 20 recommended items.

"Month/year" labeling for “best-by” dates

The best-by dates of soft drinks are generally indicated by a “date/month/year.” In order to reduce the environmental impact of inventory management along with ease of understanding for customers, Suntory Group is working to label products with the best-by date of 1 year or more as “month/year.”

Food Safety

Monitoring Product Safety

For various initiatives to monitor food safety, please see Food Safety.

Product Safety Training

Believing it vital that all employees of Suntory Beverage & Food recognize themselves as a custodian of quality and act accordingly, we continually provide quality education and awareness-raising programs via internal training and other opportunities.

Initiatives at Group Companies Outside Japan

We share common goals and values with group companies in Japan, Europe, Asia-Oceania, the Americas, and Africa, and we establish fundamental rules and systems for our activities and implement quality assurance initiatives in line with regional characteristics. Comprehensively targeting everything from water and raw ingredients to manufacturing processes and products distributed to the market, we undertake initiatives to meet quality requirements and expectations, not only of consumers but of all stakeholders.

Leveraging coordination and networking across regions outside Japan as well, we emphasize mutual development by swiftly and effectively sharing a wide range of information. We also focus on fostering talent to propel these activities, strengthening the infrastructure to enhance the sustainability of our efforts.

See Activities of Overseas Group Companies for details

Responding to Incidents

While we strive to ensure thorough quality assurance, in the event of an issue, we swiftly investigate, take action to address the affected products, and disclose information appropriately according to predetermined procedures.

For information on voluntary recalls, please see Voluntary Recalls at the Suntory Group website

Auditing for Responsible Marketing

Labeling on products is checked to ensure that it complies with relevant laws and regulations,* voluntary industry standards, and the Suntory Group’s own standards. In addition, we endeavor to use expressions that are clear, accurate and not misleading, and expressions that are easy for consumers to understand, including in advertisements and publicity.

-

*Food Sanitation Act, Food Labeling Act, JAS Act, Act against Unjustifiable Premiums and Misleading Representations, Health Promotion Act, Pharmaceutical Affairs Act, Measurement Act, Containers and Packaging Recycling Act, etc.