Initiatives in Japan

The Value of “Bottle to Bottle” Horizontal Recycling and Our Work to Achieve It

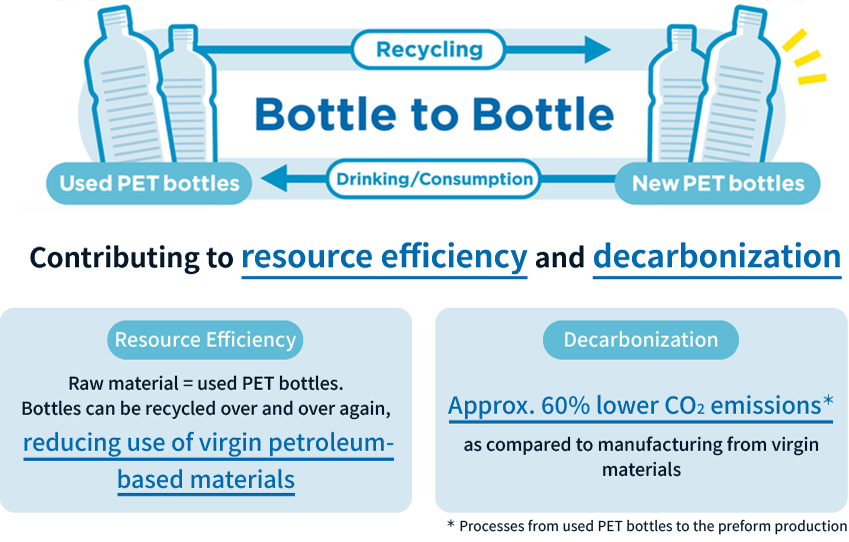

“Bottle to Bottle” Horizontal Recycling

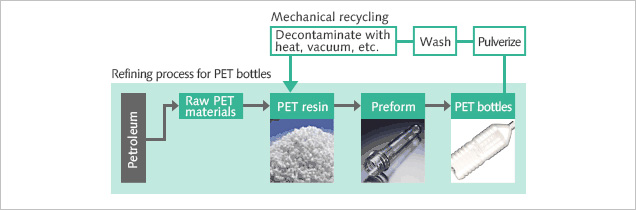

“Bottle to bottle” horizontal recycling refers to recycling used PET bottles into new ones. PET bottles are resources that can be recycled many times, which can help reduce the use of virgin petroleum-based materials and CO2 emissions. “Bottle to bottle” horizontal recycling through mechanical recycling* is a recycling method with low environmental impact (in terms of CO2 emissions during processes from raw material procurement to preform production).).

-

*Mechanical recycling: A method in which recycled resin—obtained by crushing, washing, and otherwise processing used PET bottles into a raw material to be used for new PET bottles—is further processed under high temperature and reduced pressure for a certain period of time to remove impurities in the recycled material and make PET resin of suitable quality for beverage containers.

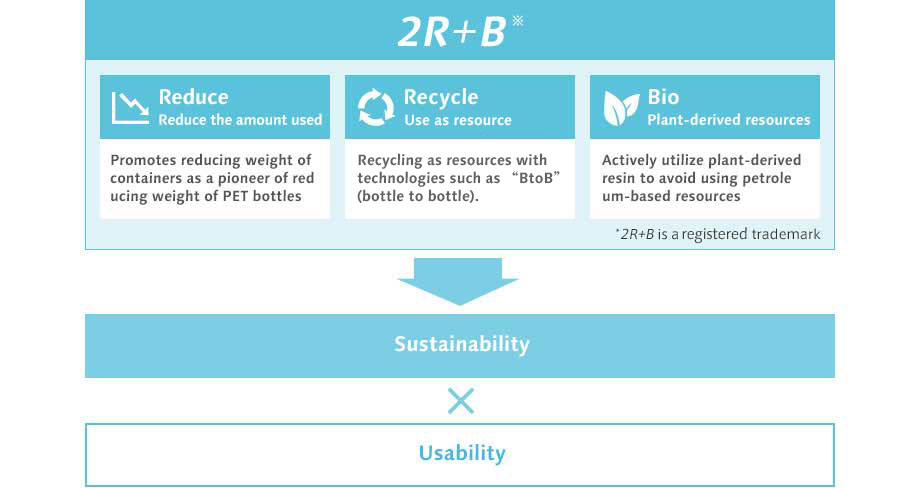

Efforts to Create 100% Sustainable PET Bottles

For over a decade, Suntory Group has been pioneering efforts toward a sustainable society by collaborating with partner companies on horizontal recycling, transforming used PET bottles into new beverage bottles. In 2011, In collaboration with Kyoei Sangyo Co., Ltd., we established the Japanese soft drink industry’s first “bottle to bottle” mechanical recycling system. The following year, in 2012, we launched the industry’s first 100% recycled PET bottle*1. This marked the beginning of a series of technological innovations, including the development of the world’s first F-to-P direct recycling technology,*2 which reduces CO2 emissions compared to conventional alternatives. With these and other initiatives, we have been furthering technological innovation and proactively commercializing and promoting “bottle to bottle” horizontal recycling over many years.

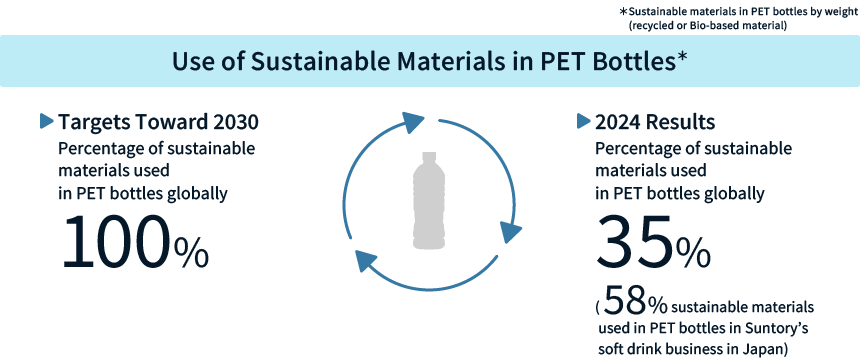

In 2019, we also established the Suntory Group Plastic Policy. In it, we set a target of achieving 100% sustainable PET bottles, switching all PET bottles used globally to 100% recycled or bio-based materials, eliminating the use of virgin petroleum-based materials by 2030. We are engaged in various initiatives to achieve this. By 2024, we expanded our use of sustainable materials (recycled or bio-based materials) to account, by weight, for 58% of all PET bottles for our soft drink business in Japan.

-

*1Mechanical recycling

-

*2Joint development among four companies including Kyoei Sangyo Co., Ltd.

Active Introduction of Recycled PET Bottles within the Group

To achieve our 2030 target of making our PET bottles 100% sustainable, we are moving forward with the adoption of recycled materials.

In Japan, we have introduced 100% recycled PET bottles for all GREEN DA-KA-RA Yasashii Mugicha (680ml, 600ml), Yasashii Rooibos (600ml), and Yasashii Corn-cha (600ml) products. Many of our other products, including Craft Boss and Iyemon, also use 100% recycled PET bottles. We have adopted the logo mark “Bottles are resources! Towards a Sustainable Bottle” on all PET bottled products* to communicate to consumers that PET bottles are a resource that can be recycled many times. In addition to our efforts within our soft drink business in Japan, all of the 720ml PET bottles used in our wine business in Japan are now 100% recycled bottles. Going forward, we will continue to pursue these efforts Group-wide.

-

*Excluding label-less products

Yasashii Mugicha 680ml

Yasashii Rooibos 600ml

Yasashii Corn-cha 600ml

Delica Maison Red 720ml

Logo “Bottles are resources! Towards a Sustainable Bottle”

Promoting Horizontal Recycling with Local Governments and Corporations

With the aim of realizing a circular society, Suntory Group is committed to “bottle to bottle” horizontal recycling—in which used PET bottles are recycled into new PET bottles—in cooperation with local governments and companies.

We have concluded “bottle to bottle” horizontal recycling agreements with distribution companies, commercial facilities, and local governments, under which we advance “bottle to bottle” horizontal recycling that takes used PET bottles collected at stores and other locations in the wider community and transforming them into new PET bottles. In addition, we offer educational programs about PET bottle recycling at elementary and middle schools within the municipalities where we have concluded agreements, as well as holding consumer awareness events at commercial and similar facilities.

Development of the “Bottle to Bottle” Horizontal Recycling System

Establishment of a Mechanical Recycling System

In 2011, in collaboration with Kyoei Sangyo Co., Ltd., Suntory Group established the Japanese soft drink industry’s first “bottle to bottle” mechanical recycling system*1 and, in 2012, published a joint research paper*2 on the safety evaluation of recycled PET bottles. Since its introduction in 2011, this system has received several environmental awards and has been recognized as a pioneering example of sustainable resource circulation.

“Bottle to bottle” horizontal recycling using mechanical recycling method makes it possible to recycle PET bottles as a resource over and over again, without using virgin petroleum-based materials. In addition, it reduces CO2 emissions by approximately 60%*3 relative to manufacturing PET bottles from virgin petroleum-based materials.

Of the PET bottle recycling systems that have been adopted in Japan, mechanical recycling is the most efficient method in terms of costs and has the lowest environmental impact (CO2 emissions).*4 While the recycling process may add some color to the bottles, it does not affect the quality or safety of the containers in any way.

-

*1Mechanical recycling system: A method in which recycled resin—obtained by crushing, washing, and otherwise processing used PET bottles into a raw material to be used for new PET bottles—is further processed under high temperature and reduced pressure for a certain period of time to remove impurities in the recycled material and make PET resin of suitable quality for beverage containers.

-

*2Japanese Journal of Food Chemistry and Safety, Vol. 19 (1), 2012, pp. 7–13

-

*3Processes from used PET bottles to the preform production

-

*4Based on our research

Adoption of F-to-P direct recycling technology

In 2017, we collaborated with Kyoei Sangyo Co., Ltd. and overseas machinery manufacturers (EREMA in Austria and SIPA in Italy) to develop F-to-P direct recycling technology, which promises to further reduce our environmental impact. We began production in the fall of 2018. F-to-P direct recycling technology is a technology that can directly manufacture preforms after melting and filtering flakes made from collected PET bottles that have been crushed and washed at high temperatures. The F-to-P direct recycling technology can reduce CO2 emissions by 70%* compared with PET bottles made of virgin petroleum-based materials.

Example products that use F-to-P direct recycling technology

F-to-P direct recycling technology process

-

*Processes from used PET bottles to the preform production

Awareness-Raising Activities to Promoting “Bottle to Bottle” Horizontal Recycling

Engaging in Awareness-Raising Activities

To realize a sustainable society, Suntory Group has been working to promote understanding of horizontal recycling initiatives and encourage proper sorting of used PET bottles by engaging in events such as seminars for external audiences. In 2021, we signed an agreement with Waseda University on the realization of a resource-circulating society, and we are also making efforts for the next generation. At elementary and junior high schools in municipalities with which we have concluded bottle to bottle” horizontal recycling agreements, we offer educational programs on the importance of promoting “bottle to bottle” horizontal recycling and how to properly sort PET bottles, providing an opportunity for students to think about recycling and resource circulation. At companies with which we have concluded these agreements, we also hold educational seminars for employees and events for their families.

Communication with Consumers

Since 2022, driven by the desire for people to view PET bottles not as garbage but as a resource, and of recycling bins not as garbage bins but as something more like postal boxes that “deliver” the resource to the next person, we have been holding “PET bottle post” events and proactively communicating with consumers and engaging in awareness-raising activities on the theme of proper sorting not only at home but also when out and about.

PET bottle post

Promoting Horizontal Recycling Through Industry Cooperation

Since 2022, we have been rolling out installation of recycling boxes with industry-standard specifications in outdoor areas, where PET bottles are often not properly sorted from other waste.

New recycling boxes with innovations such as a downward-facing insertion slot have been shown to reduce the amount of foreign matter put into them. This improves the quality of collected PET bottles and contributes to “bottle to bottle” horizontal recycling. Using recycling boxes with industry-standard specifications will improve efficiency for vending machine operators and recycling processes and promote PET bottle resource circularity.

For more information, visit the Japan Soft Drink Association website

“Bottle to Bottle” Horizontal Recycling Progress Through Packaging Improvements

In order to further promote “bottle to bottle” horizontal recycling, we believe that making it easy for consumers to sort their PET bottles from other waste is an important factor.

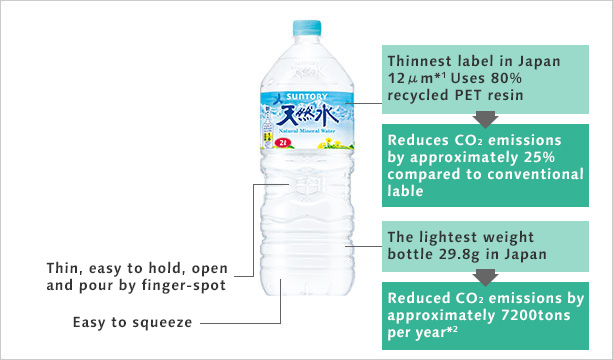

Suntory Group therefore introduced label-free bottles in 2020 and have adopted them for flagship products including the Suntory Tennensui (Mineral Water), Craft Boss, and Iyemon brands. This move eliminates the task of removing bottle labels, making it easier to prepare them for recycling. We hope this will contribute to further encouraging “bottle to bottle” horizontal recycling.

In addition, we developed and launched in April 2023 a new 2L PET bottles for Suntory Tennensui that is easy to crush down to approximately one-sixth of its original size when empty. This new bottle resolves frustrations related to storing empty PET bottles in the home until recycling collection day, such as bottles taking up space or popping back to their original size even after crushing. By making it a more satisfying process to engage with, we also hope to encourage customers to remove caps and labels when they sort their bottles for recycling, leading to higher-quality PET bottle recycling.

Initiatives Outside Japan

Introducing Recycled PET Bottles Overseas

Suntory Beverage & Food Europe (SBFE)—which operates principally in the UK, France, and Spain—has also been pursuing initiatives aimed at making its PET bottles 100% sustainable by 2030. MayTea and Pulco introduced 100% recycled PET bottles in France in 2021, following the example of Ribena, which had already done so in the UK. In 2022, Suntory Beverage & Food Europe has started 100% recycled PET bottles in its Lucozade Sport brand in the UK and Ireland. These initiatives allowed us to increase the proportion of recycled plastic (rPET) used in SBFE PET bottles from 36% in 2022 to 44% in 2023.

In addition, Suntory Beverage & Food Asia Pacific, which operates principally in Vietnam and Thailand, introduced 100% recycled PET bottles in Vietnam in 2022 (the first such bottles used by Suntory Group in Asia) and in Thailand in 2023 (a first for the country).

Ribena’s 100% recycled PET bottle

Development of New Technology to Drive Horizontal Recycling

SBFE is participating in a consortium with green biotech company Carbios. In June 2021, the consortium successfully developed the world’s first PET bottle of food-grade quality made from chemical recycling using enzymatic technology*. A prototype was made for SBFE’s Orangina brand, and a Japanese technical team helped test aspects of the prototype that Carbios could not manage, including the safety and ease of manufacturing the bottle. In September 2021, Carbios opened its first demonstration plant with the goal of launching commercial plant operations in 2027. This innovative technology breaks down polyethylene terephthalate (PET) into its building blocks using a special enzyme that only breaks down PET plastic to create the raw materials of PET bottles that can then be reused. This technology is expected to enable an end recycled product on par with virgin PET, even when using source PET bottles not optimally separated from other waste or including a high proportion of colored PET bottles (common in Europe).

-

*Based on our research