Lightweighting of PET Bottles

The 550ml Suntory Tennensui (Mineral Water) PET bottle (excluding products for vending machines) was developed by Suntory and is the lightest such bottle made in Japan* (11.9 g).

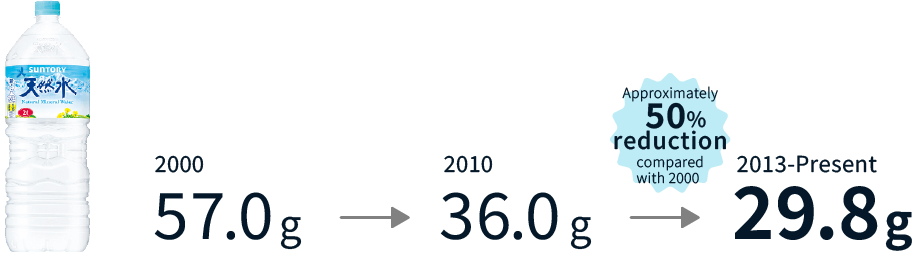

Compared with PET bottles from 2000, bottle weight has been reduced by around 50%. Additionally, with 30% plant-based materials used, the usage of virgin petroleum-based materials has decreased by over 60% per bottle since 2000. Similarly, for the 2L bottles, bottle weight has been reduced by around 50% and includes 30% plant-based materials, achieving a reduction of virgin petroleum-based material usage by more than 60% per bottle compared to 2000.

-

*PET bottles for mineral water (500 ml to 600 ml) in Japan. As of April 2025

Change in Weight of 550ml Suntory Tennensui PET Bottles*1

-

*1500-ml capacity through 2009

Change in Weight of 2L Suntory Tennensui PET Bottles

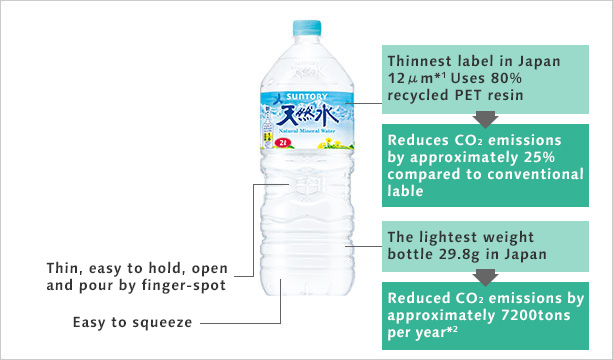

Thinnest Roll Label*1 for PET Bottle Beverages in Japan

We are also working to reduce environmental impact by thinning the labels on PET bottle products. We achieved the thinnest PET bottle roll label in Japan at 16 ㎛*2 in 2012. We are using an even thinner label of 12 ㎛ for the 2L and 550ml PET bottles of Suntory Tennensui in 2014 and now use these labels on all our products with roll labels. This has allowed us to reduce CO2 emissions by 25%*3 compared to the conventional (16 ㎛) labels.

-

*1Labels that peel off from the glued area instead of peeling off at the perforations

-

*21/1,000 mm

-

*3Reduction rate in the film (label) manufacturing process

Japan's thinnest roll label at 12μm thickness

Introduction of water-based flexographic printing and water-developed flexo plates to reduce CO2 emissions during label manufacturing

Suntory Group is advancing the transition to water-based flexographic printing for the manufacturing of labels for a wide range of products, including Suntory Green Tea Iyemon, Suntory Tennensui , Suntory Oolong Tea, GREEN DA・KA・RA, and GREEN DA・KA・RA Barley Tea, reducing CO2 emissions during label production by more than half compared to traditional oil-based gravure printing. Moreover, in 2024, the water-developed flexo plates, which can reduce CO2 emissions by about 30% during label plate production, were introduced for the first time*1 in the domestic beverage industry for the labels of Suntory Tennensui 550ml PET bottles manufactured at the Suntory Kyushu Kumamoto Plant.

-

*1:Based on our research

Lightest PET Bottle Caps in Japan

We are also reducing the environmental impact of our PET bottle caps. Since 2016, we have adopted 1.85g bottle caps, which are the lightest in Japan*1 and use 30% plant-based material, for Suntory Tennensui. This innovation reduces the use of petroleum-based material by around 35%*2 and decreases CO2 emissions by around 27% compared to conventional PET bottle caps.

In addition, we use recycled pellets from used caps as part of seed pots for Suntory Flowers.

-

*1As of April 2025

-

*2Per bottle of the Suntory Tennensui natural mineral water (550 ml)

Development of PET Bottles in the Alcoholic Beverage Business

We are taking great advantage of the technology cultivated in our soft drink business in our alcoholic beverage business. Suntory Spirits Ltd. has launched the 4L PET bottle weighing 110g, which is the lightest in Japan, for whisky products such as Kakubin, Torys and other alcoholic products starting from June 2016. By making it up to 18% lighter than the conventional 134g or 120g, the use of PET resin is reduced, resulting in an annual CO2 emissions reduction of approximately 460 tons(17%)*. We have also removed the grip used on conventional PET bottles and adopted a new deep grip section in the center of the bottle for ease of use in collaboration with the PET bottle manufacturer.

-

*Based on our calculations

Old 4L PET bottle and

new lightweight 4L PET bottle

Development of World’s Lightest* Heat-resistant PET Bottle in Southeast Asia

The Japanese manufacturing technology and design capabilities for reducing weight of PET bottles have been used to introduce lightweight PET bottles in Group companies in Europe and Asia. In 2020, we succeeded in developing the world’s lightest* heat-resistant PET bottle weighing 15g that also pursues functionality, versatility, and design. This heat-resistant PET bottle utilizes technology that prevents deformation of the bottle by dropping nitrogen to create positive pressure.

We have introduced this bottle to Suntory PepsiCo Beverage (Thailand) and Suntory PepsiCo Vietnam Beverage (Vietnam). We also introduced 100% recycled materials for these bottles from 2023.

-

*In the 450-ml class of heat-resistant PET bottles (as of April 2025, according to our own research)

Lightest heat-resistant bottle with liquid nitrogen injection in Southeast Asia

Introduction of In-house PET Bottle Production Technology at Suntory Global Spirits

Suntory Global Spirits introduced in-house bottle production technology for the first time for large 1.75L spirits bottles in 2017. This in-house production not only achieved a 14% reduction in bottle weight but also significantly improved transport efficiency by shifting from bottle transportation to preform transportation, greatly contributing to reducing environmental impact.

We introduced even lighter bottles in 2023, and reduced the bottle weight by approximately 26% compared to before the introduction of in-house production in 2017. We are also considering using this in-house bottle production technology to further development across other sizes, such as 100ml to 1L.

Initiatives to Reduce Weight at Suntory Beverage & Food Europe

Suntory Beverage & Food Europe is also working on reducing the weight of other packaging materials such as cardboard and metal. In Spain, the company changed the structure of the cardboard ring used to bundle cans (from PremCollar to CanCollar), reducing the amount of cardboard used by 231 tons and cutting annual CO2 emissions by 226 tons. The 330ml steel can and 250ml can have also been changed to aluminum, achieving significant weight reduction.